Dreams Made Concrete®

facade systems

Lorem ipsum

Lorem ipsum

Let's create something special together

If you have any questions, suggestions or interest in cooperation, please do not hesitate to contact us.

Text sections:

the yellow button is made by the yellow-button-text class on the button

We transform architectural visions into reality using methods that surpass current technology.

Defining new standards for sustainable architecture

Through innovative materials and processes, we reduce energy and material consumption, contributing to a better future for us all.

85 %

Optimisation of the façade system topology leads to a reduction in the amount of material used

50 %

Technology saves up to 50% of CO2 production compared to conventional building approaches

70 %

Percentage of recyclable materials used in our façade solutions

85 %

Optimisation of the façade system topology leads to a reduction in the amount of material used

Key advantages of So Concrete technology

01

Topological optimization

Using advanced topological optimization algorithms, So Concrete achieves maximum material and load efficiency for structures. This process allows the design of each project to be optimized to be not only stronger and lighter, but also more material and energy efficient.

02

Unique UHPC and UHPFRC

Ultra-High Performance Concrete (UHPC) and Ultra-High Performance Fibre Concrete (UHPFRC) are key materials that So Concrete uses to achieve exceptional durability and mechanical strength. These materials allow for thinner and more aesthetically appealing structures that are also extremely weather and wear resistant.

03

Robotic Fabrication

Revolutionary 3D printing technology enables So Concrete to produce complex structural elements accurately and efficiently. Robotic fabrication not only speeds up production processes and increases accuracy, but also enables the creation of unique geometric shapes that would otherwise be difficult to realise.

04

Sustainability

Thanks to innovative production methods and efficient design, So Concrete reduces material consumption by up to 60%. This approach not only reduces the environmental impact of the construction industry, but also leads to significant savings in material and transport costs.

05

Comprehensive building solutions

So Concrete offers a complete construction solution including planning, production, transportation and installation. The integration of all these services under one roof ensures the smooth running of projects, from initial design to final implementation.

06

High aesthetics

The aesthetic possibilities of the materials and technologies So Concrete uses are virtually limitless. The company's emphasis on visual quality and design makes it a leader in innovative and aesthetically appealing construction that can deliver visually stunning projects with lasting value.

Harmonica:

Explore the possibilities of So Concrete facade systems

UHPC or UHPFRC material

the possibility of using certified construction recyclates in the material mix

only 30% of the material used compared to conventional methods

minimal material absorption extends the service life of the solution many times over

Hidden anchoring with integrated anchoring elements directly into the facade elements

hanging of the elements on a prepared structure on the building shell

integrated reinforcement ensures the rigidity of the individual façade elements in the area

façade solutions assembled from custom-made elements according to customer requirements

the standard thickness of the elements is 30 mm + local reinforcement at the reinforcement ribs

overall dimensions are individual with regard to design, statics, handling and transport

the maximum size of the elements is not limited by production

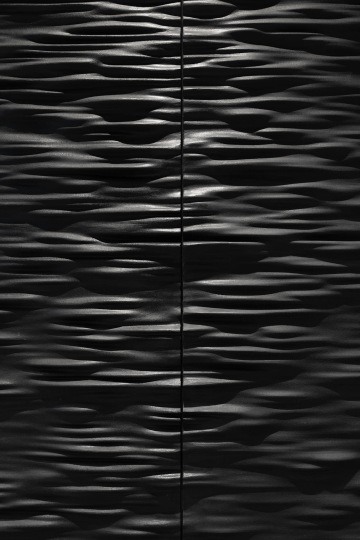

planar and dynamic shapes

the chosen motif is linked to the individual elements of the façade system

Surface finish according to architectural design, from awarded 3DCP to washed, blasted or smooth surfaces

colour according to the current So Concrete RAL pattern

colour according to the chosen aggregate or construction recyclate

Headquarters

So Concrete a.s.

Pobřežní 667/78

186 00 Prague 8 - Karlín

ID: 28212126

DIC: CZ28212126

Establishment

So Concrete a.s.

Jankovcova 1635/57b

170 04 Prague 7 - Holešovice

Project Consultant

Jana Čepková

jana.cepkova@so-concrete.com

+420 721 462 398

Marketing and media

Jáchym Klimko

office@so-concrete.com

+420 774 091 217

Image + text

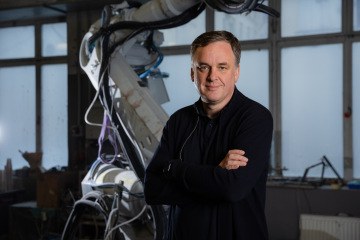

Robotic fabrication, not 3D printing

"It's not just about 3D printing, our robots also work with bending or milling products, which gives them an extra dimension, especially aesthetically, but also allows for precise and easy assembly on site. This is a very complex production system, which is why we talk about robotic fabrication," explains project manager Jana Čepková.

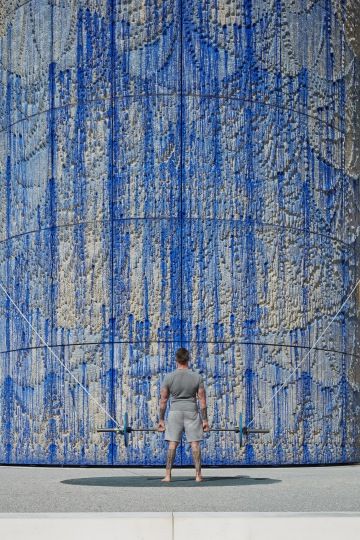

Concrete building façade systems that combine static and aesthetic functions, allowing for a unique morphology for each project.

Multidisciplinary team

Comprehensive support for clients in the field of digital concrete is provided by a multidisciplinary team consisting of professionals from the fields of building design and statics, materials technology, designers, programmers and robotics experts.

Jan Novák

Jan Novák

Jana Nováková

Jan Novák

The technology and production centre in Prague Holešovice provides more than 1000 m2 of facilities for the realization of the entire range of serial products and individual projects. It currently has three robotic workstations that allow printing of individual objects up to 3 × 8 m. All services are delivered locally and internationally.

Logos:

we create together

Gallery:

Images with content after hiring:

Need to add a class chip to the image

Unique facade system technology

Maximally optimized products are based on the careful development of orders that require unique static and aesthetic solutions.

Forms

Write to us

Projects - database extracts:

So Concrete facades in completed projects

Our façade systems offer optimal, technologically advanced solutions for a wide range of projects, from commercial buildings to large-scale residential complexes.

Never-ending research

Take a look at our projects and technologies at the edge of possibility, which are the result of intensive research and development and allow us to go beyond the usual boundaries in architecture and design.

Projects - manual blocks in LB

box, 2x photos and text with link in it

box has hover-box class

It is necessary that both photos are in the same aspect ratio. Otherwise it will be wrong

News - listing:

What's going on

Take the pulse of our company with the latest news and innovations that define our direction and inspire us.

Pavel Grečner, Technical Director of So Concrete

“Let’s think ahead.” This quote from one of our presidents perfectly captures the mindset of Pavel Grečner, Technical Director at So Concrete.

Impact test of facade elements for the OLOE office building

The OLOE office building, which is part of the southern part of Prague's vast new Smíchov City district, will receive a facade, the first segments of which are currently being tested as part of the so-called impact test.

Marie Kovářová, CEO of So Concrete

"Everything is possible when there’s a will. And a good team can achieve much more than any individual," says Marie Kovářová, the new CEO of So Concrete.

CTA above the footplate

Arrow-shaped button:

anchor-btn-down for downward arrow

anchor-btn-up for up arrow

by default the arrow is black with a white background and the colours swap on hover

class yellow adds a yellow background to the hover then works as the default arrow

Classes can be combined.