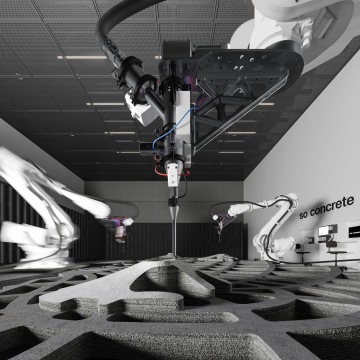

Facades and wall cladding, columns, interior accessories, and even complete buildings. These can all be custom made by So Concrete using robotic fabrication for a variety of clients such as developers, architects, construction companies, and private investors.

Share article

Facades and wall cladding, columns, interior accessories, and even complete buildings. These can all be custom made by So Concrete using robotic fabrication for a variety of clients such as developers, architects, construction companies, and private investors.

Before producing a specific product, a detailed design optimization process is conducted to maximize the potential of robotic fabrication technology and streamline the entire project. “This allows us to signifi cantly speed up the production process and, for example, achieve a substantial reduction in material usage, which also leads to financial savings,” explains project manager Jana Čepková. “For instance, a client approached us regarding facade panels which they expected to be at least 12 centimeters thick.

We were able to reduce this to just 3 centimeters thick.” Design optimization involves consulting with the client over a specific project and then within the So Concrete team. Different strategies can be chosen for each type of commission, from design processing, through material selection, to final product processing. Robotic fabrication offers a range of procedures that can be adapted to a specific intention. At the end of the design optimization process, a specific price and delivery time are determined.

As Jana Čepková describes the process: “Since each project is individual and unique, we also prepare various samples and prototypes which we use to fine-tune details. Only then do we prepare the production documentation for our robots. It is important for us to provide clients with a comprehensive service–from the initial project consultation through design assistance and onto production and delivery. It is essentially about optimizing the entire process of using our technology.”

Share article

More news

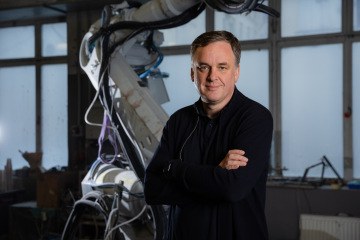

Pavel Grečner, Technical Director of So Concrete

“Let’s think ahead.” This quote from one of our presidents perfectly captures the mindset of Pavel Grečner, Technical Director at So Concrete.

Impact test of facade elements for the OLOE office building

The OLOE office building, which is part of the southern part of Prague's vast new Smíchov City district, will receive a facade, the first segments of which are currently being tested as part of the so-called impact test.

Marie Kovářová, CEO of So Concrete

"Everything is possible when there’s a will. And a good team can achieve much more than any individual," says Marie Kovářová, the new CEO of So Concrete.